Quality and Productivity: Two Factors that go hand in hand for Könst

For over 40 years now, the Könst family has been specializing in breeding Alstroemeria. Originally based out of the Netherlands, Könst Alstroemeria is one of the leading breeders of Alstroemeria flowers, with a wide-spanning assortment of varieties in a range of colors, shapes, and sizes which are sold to growers all over the world.

In 2007 the company founded Flores la Serena, a 5 ha propagation operation in Colombia. Located 2600 meters above sea level, just outside of Bogota, Flores La Serena is well situated to allow Könst Alstroemeria to develop the premium varieties for the South American market.

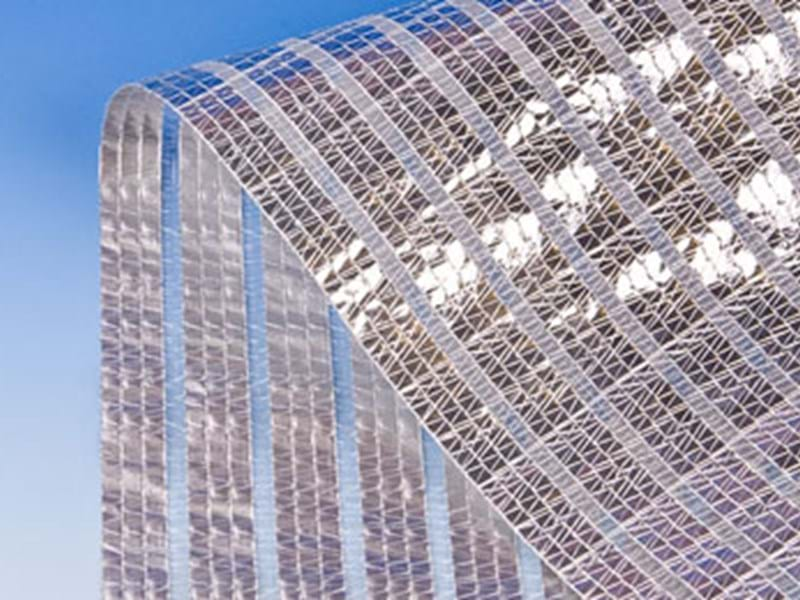

Flores la Serena recently completed the construction of a new greenhouse equipped with Svensson climate screens to create the optimal climatic growing conditions for Alstroemeria. Harmony and Tempa screens work to maintain the ideal climate levels in the greenhouse, both during the day and at night. An open, light-diffusing Harmony 6420 O E screen helps reduce radiation levels during the day to avoid burning the plant foliage. And a second, closed Tempa 7562 D FB screen helps the operation withstand the internal temperature of the greenhouse at night, keeping heat inside and reducing energy costs.

Cesar Guzmán, who oversees the management of the Colombian cultivation facility, shares his experience using Svensson screens for climate control in Flores la Serena’s 1,000m2 propagation area.

“The challenges we have previously faced in conventional greenhouses are high relative humidity and extreme temperatures that are either above or below the desired range. The temperature levels required by our crop are between 14 to 26°C (57-79°F), with a relative humidity range of not less than 55% and maximums of 85%”, says Guzmán.

Phase 1, Acclimatization

“The most critical process is carried out in this phase since the plant requires greater care, and we seek optimum hardening. Previously this process took us six weeks, but with our new climate screen technology, we were able to reduce the process to just four weeks,” notes Guzmán.

Phase 2, Hardening

In Phase 2 or "Hardening", we generate climate conditions for the plant to strengthen, acclimatizing the plants for later cultivation in greenhouses throughout the region. Previously this process took us eight weeks; currently, we’re able to complete it in only six weeks.

Reduced Production Comes with Increased Savings

“The ability to better manage our climate has ultimately allowed us to reduce our production times, we’ve been able to save up to as much as 30% in fertilization and have lowered our labor costs. And although we now occupy a smaller production area, we’ve proved to be much more productive, for the same volume of plants."

“By producing seedlings in conditions that are optimal for the production phase, we’ve been able to increase our propagation production by up to 30%. Our Harmony and Tempa screens have contributed greatly to our increased production capabilities.”

Cesar Guzmán concludes, “In the case of plants, time is productivity. The more seedlings I have per area and the shorter my cycles, the more productive I am.”