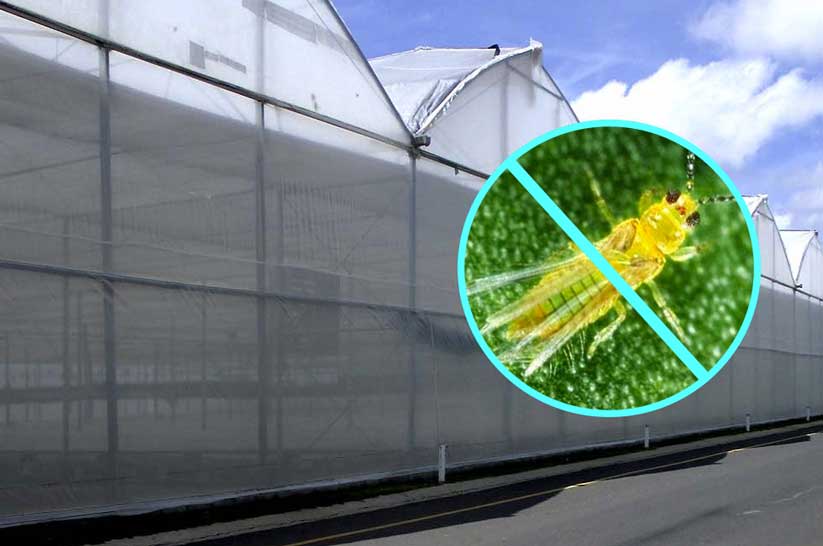

An insect screen that offers effective thrip control without compromising ventilation

This article featured in Koppert’s Biojournal highlights the importance of taking a comprehensive approach to thrip exclusion and examines why precision and special attention to quality insect meshes is critical.

The westerns flower thrips (frankliniella occidentalis) or thrips, are very dangerous pests in greenhouses. They feed on flowers and vegetative material, and have the ability to do great damage because they carry viruses. They have spread rapidly throughout the continent due to the transport of shipments containing materials and plants.

Thrips are very thin and slippery, hide very well in the leaves and deep within flowers, and their reproductive cycle is very difficult to stop. Therefore, often pesticides are merely not effective enough to offer total control.

Temperature is a factor

In order to combat thrips, a comprehensive approach is necessary and requires a preventive strategy of biological control, including beneficial insects and constant monitoring with gum traps. The problems caused by thrips continue to escalate in practically all regions.

The reproduction rate of thrips depends mainly on the temperature and thus can increase more rapidly around 30º C. This unusual and rapid multiplication of the thrip population is due, in part, to the relatively warmer winters in recent years, which can be even more devastating when cooling is insufficient.

In addition, thrips can easily survive during the winter months in greenhouses when there is a combination of inadequate prevention and control and their developed resistance to pesticides.

The use of an insect screen for the exclusion of thrips seems to be an obvious and simple solution, however the selection process requires adequate consideration, as careful attention to the mesh design, functionality and properties must be evaluated.

The use of micromesh is often highly recommended to operations that are affected by thrips pressure. It’s necessary to break the cycle from the start, especially in cases that are being heavily affected by thrips pressure.

For propagators that are sending vegetative material to other greenhouses to be transplanted, it is important to break the emission and transport cycle by starting with a clean cycle that is free of thrips.

What kind of mesh insect netting is required?

In the early 90's, a significant number of investigations related to micromesh were conducted. Findings reported that due to their slender bodies, thrips could only be excluded by a mesh netting with very thin holes. The maximum recommended hole size dimension for the exclusion of western flower thrips is 192 microns (μm), which means that hole sizes should be just large enough for a strand of human hair (whose diameter ranges from 170 to 181μm) to pass through. A problem that arises as a result of reducing the size of the holes in the netting is the increase in the number of threads per cm², and this translates directly into an increase in the area they occupy along with a reduction in airflow causing heat buildup in the greenhouse.

Block pests not airflow with Econet insect exclusion screens

To solve the problem of having an insect net with a distance between the yarns measuring 192 μm without compromising airflow, Svensson developed ECONET insect screens. Econet insect screens are uniquely designed with a higher porosity potential than other conventional meshes, and have more consistent hole sizes than standard insect screens which creates the ability to keep specific pests such as thrips out of the greenhouse while maintaining adequate ventilation.

Recently in Latin America, more emphasis has been given to the importance of quality mesh insect netting. The technical specifications required of suppliers have increased and special attention has been given to the way in which they are manufactured. Experienced producers require geometrical hole specifications that correspond to those that are necessary to exclude specific insect types using a highly porous design that to ensures proper airflow into the greenhouse. Such initiatives led to the study conducted at the Postgraduate College (COLPOS) in Texcoco, State of Mexico. Samples of thrips collected in the state of Querétaro along with samples of insect nets from different manufactures were sent to the COLPOS laboratories to determine the exact measurement and size of thrips, and which insect nets could best exclude the insect.

The study was facilitated by the head of the entomology and microscopy department at COLPOS, Jorge Valdez (jvaldez@colpos.mx), Master of Science.

The below images are taken through a microscope and show the different netting types and thrips to compare their geometry. Here, images to scale are presented and can be seen in an electron microscope. This clearly presents the thrip's unique size and mesh structure, showing why effective exclusion is so precise.

Good advice

Making the right choice when it comes to selecting high quality mesh insect screening is what allows for the best form of thrip prevention, and proper operational practices and maintenance are also very important. Always make sure that employees are following good cultivation practices and that there is compliance at all times with established protocols for entering and exiting the greenhouse. This will help to avoid bringing thrips in through clothing, hair, tools or carts, whicle also preventing the transfer of thrips from one greenhouse to another.

Periodically check for tears in the insect nets that are commonly caused by the windows or zippers themselves. Any tears or damages are "entrance invitations" for thrips. Insect screens can be repaired with a patch of the same material, sealing the perimeters with a bit of silicone. Another suggestion is to keep the insect netting clean and free of dust and mud. This can be done by washing the screens with water and soap using a soft brush; or using a pressure washer that is not used excessively or at high pressure levels and bearing in mind that this has the risk to increase the seperation between the wires of the material.

Svensson Climate Solution:

ECONET 1535